Last week, Jama Software launched Jama Connect® for Medical Device Development, which helps teams speed time-to-market without compromising quality or compliance.

In our experience working with more than 200 medical device developers, we’ve realized how important it is to create best practices for risk management under ISO 14971, the FDA’s mandatory standard for risk assessment throughout the product development lifecycle.

In this post, we’ll outline the main clauses of ISO 14971 and explain how Jama Connect can help medical device developers build better, safer products that satisfy ISO 14971.

What is ISO 14971?

ISO 14971 is an international standard that sees risk management as a product lifecycle process encompassing the development, production, and post-production stages. Jama Connect offers a straightforward approach to managing risk according to ISO 14971 in one platform. The standard was updated in 2019, providing more guidance on risk management and adding more detailed requirements.

Managing Risks & Requirements for ISO 14971

Risk management is an inextricable part of the medical device development process. For medical device developers, risks are a core principle of product development and should be tied together in one powerful platform.

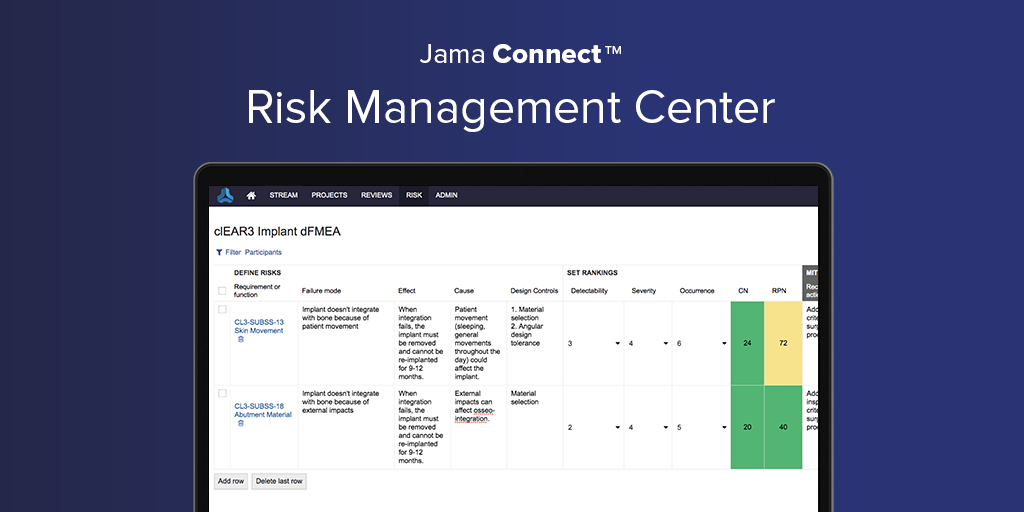

Many medical device companies continue to depend on Excel to capture risk data, but Excel simply can’t provide the end-to-end traceability necessary for satisfying ISO 14971. That’s where Jama Connect comes in: It allows teams to easily connect risks, requirements, and testing in one system where requirements and test results stay live in real-time.

Jama Connect and ISO 14971

Jama Connect guides compliance with Clauses 4 through 7 of ISO 14971, which covers how risk should be managed throughout the product development process.

RELATED: Understanding Integrated Risk Management for Medical Device

Risk Management Plan

Clause 4 of ISO 14971 concerns how risk is organized and administered for your product line. It requires the formation of a Risk Management Plan throughout the development lifecycle.

The Risk Management Plan is the record of a planned process for risk management: who does what and when, how risks are scored, etc. It’s a component of the Risk Management File, which contains all the outputs for risk.

Clause 5: Risk Analysis

Clause 5 of ISO 14971 requires that medical device developers identify potential hazards and hazardous situations. Each hazardous situation and its potential consequences must be evaluated. Jama Connect helps teams satisfy Clause 5 by defining device-specific hazards and capturing risk probability and severity.

Jama Connect offers risk management item templates to capture important information about the risk analysis process, including a description of the device, intended use, and the scope of the analysis.

Teams can identify and evaluate potential hazards, sequences of events, hazardous situations, and harms in a single item type.

Clause 6: Risk Evaluation

Clause 6 requires the evaluation of risk for each hazardous situation and the definition of acceptability criteria for determining when risk reduction is required. To satisfy Clause 6, teams take the inputs from Clause 5 and determine the risk level for each hazardous situation.

In Jama Connect, risk acceptability criteria can be customized for a particular product line or medical device classification in the risk management item.

RELATED: Understanding FDA Medical Device Class and Classifications, and its Impact on Requirements Management

Clause 7: Risk Control

Clause 7 requires risk control measures to be developed, implemented, and verified across the product development lifecycle. Risk control measures could include product design, preventative measures in the product, and labeling. Residual risk must be evaluated against acceptability criteria, and risk control measures must be reviewed in case additional risks have been introduced inadvertently.

The risk evaluation item lets users identify risk control options for a specific hazardous situation, such as inherent safety by design, protective measures in the medical device or manufacturing process, and safety information.

Risk control measures, implementation verification, and verification of risk control effectiveness can also be accounted for in the risk evaluation item. Links to system requirements and verifications in Jama Connect can easily be created from the risk item to demonstrate traceability from hazardous situations to risk controls.

Clause 8: Residual Risk

Clause 8 requires an evaluation of the medical device’s overall residual risk. If the overall residual risk is unacceptable, it must be demonstrated that the medical benefit outweighs the residual risk.

When defining risk control measures, teams can capture those measures in Jama Connect and link them directly to risks before updating the rankings to determine the residual risk level.

With traceability through all phases of risk, users can quickly identify potential pitfalls in the product development process and address them before they become bigger barriers to success.

The Bottom Line

ISO 14971 requires a cohesive, well-documented narrative of your product’s lifecycle to assure the FDA that the device is safe, effective, and compliant. Any decisions or actions that aren’t documented could keep your product from reaching the market or result in a recall.

Finding and fixing errors early in the product lifecycle saves money, speeds time to market, and improves product quality. Jama Connect allows medical device developers to review risks and risk controls holistically so that teams can operate with confidence.

From a compliance perspective, the Jama Connect for Medical Device Development illuminates the risk management and product development process, while simultaneously generating the required documentation to support that narrative.

For a deeper dive into ISO 14971 and how Jama Connect for Medical Device Development offers a comprehensive way to manage risk and requirements throughout development, download our white paper, “Application of Risk Analysis Techniques in Jama Connect to Satisfy ISO 14971.”