Jama Software is always on the lookout for news and content to benefit and inform our industry partners. As such, we’ve curated a series of articles that we found insightful. In this blog post, we share content sourced from Supply Chain Dive – Robotics and Automation Go Mainstream – which was originally published on January 25, 2022, by Jen A. Miller.

Robotics and Automation Go Mainstream

Editor’s note: This article is the latest in a series that looks into the ways supply chains, warehouses and manufacturing facilities are investing in technology. Here’s the previous story.

Robots are often in the news for sensational reasons: The Boston Dynamics robot dog impersonates Mick Jagger; a Spider-Man “stuntronic” flies over Disneyland visitors.

But in supply chain, robotics and automation have gone from something radical, even fringe, to mainstream.

“It’s considered low risk. And, pretty soon, it’s going to be table stakes for operations within supply chain, where 10 years ago it was considered either cutting, or bleeding edge, or risky,” said Jeff Christensen, vice president of product at Seegrid.

Annual installations of industrial robots will jump from 450,000 a year in 2015 to 600,000 in 2022, according to a McKinsey projection. The firm also predicted that 10% of today’s manufacturing processes will be replaced by additive manufacturing by 2030.

A confluence of factors — including the pandemic, labor shortages, and technology maturing at the right time — is pushing robotics ahead in 2021 and beyond.

Robotics mature, along with AI

Like most technologies, robots became more widespread when they improved as a technology, and when they dropped in price.

The introduction of the robots-as-a-service model has allowed enterprises to supplement their operations when they need help, or try adding robots without having to make a major capital investment.

“Pretty soon, [robotics and automation are] going to be table stakes for operations within supply chain.”

Jeff Christensen, Vice President of Product at Seegrid

The progression of artificial intelligence has also helped, said Christensen. The sheer amount of data being collected changes what’s possible. What people can do on any computing device today is vastly different than 10 or 20 years ago.

Better robots, better sensors and AI “have hit the maturity threshold at the right time, at the time the market demands what it needs to do,” Christensen said. “That doesn’t always happen. Lots of time there is technology that comes to maturity in a vacuum or in a lab with no real key demand for it.”

Related: Regulatory Shift for Machine Learning in Software as a Medical Device (SaMD)

A pandemic push

Right now, there is demand: increased e-commerce business, labor shortages, truck driver shortages and instability in the supply chain has robots stepping up to the plate, especially when it comes to building resiliency.

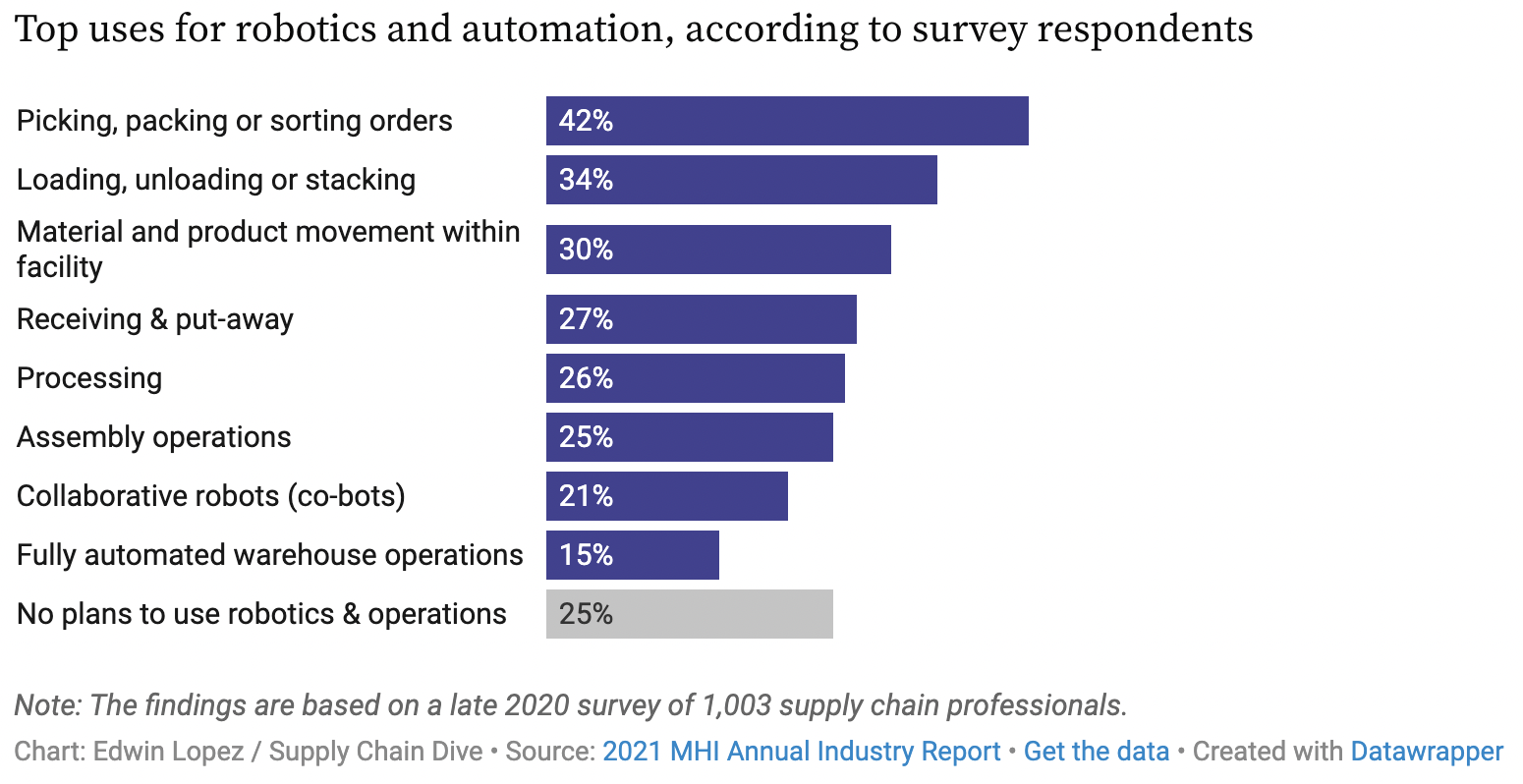

In the 2021 MHI Annual Industry Report, 53% of the more than 1,000 supply chain professionals surveyed said they were increasing or substantially increasing their investment in robotics and automation to make the supply chain more resilient. The study also found that 38% have robotics and automation in use today and an additional 38% predict it will be in use within five years.

How businesses plan to step up robotics investments

The need for efficiency and error reduction is pushing robotics and automation in manufacturing, too, especially for companies working on the COVID-19 response.

The pandemic has put a “particular strain” on diagnostics companies, Samantha Betancourt, vice president of supply chain and external operations at Ortho Clinical Diagnostics, said via email.

“We are seeing our volumes increase at the same time we may have to limit the number of people in a facility. That made us realize we need to find more creative ways to ensure we could continue to move our products even when [we’re] limited by the ability to physically touch the products,” Betancourt wrote.

She said assigning tasks to robots also allows their team members “to be thought leaders,” which is critical right now. “Employees can focus on strategic work and leave repetitive activities, whether in a spreadsheet or in a warehouse, to robotics.”

Related: Automotive Engineering and Management Methods for Modern Vehicle Development – Implementing Functional Safety for Autonomous Driving

Overcoming hurdles to adoption

While robots are becoming more common, they’re still new and “with anything new, there needs to be time to build trust,” wrote Betancourt.

“Until team members are used to working alongside robots and can truly trust their work product, oversight adds additional tasks,” she said.

Not every company has the money to make a capital investment right now, either. That, plus concerns about maintenance and upkeep costs, are keeping companies on the sidelines, said Bill Ferrell, supply chain professor and associate dean of the Graduate School at Clemson University.

Seeing successful applications in other enterprises will help, Ferrell added. He pointed to autonomous forklifts already being used in warehouses and Walmart’s roll out of autonomous trucks.

“We’re starting to see the beginning of applications and implementation in the real world,” he said. “It’s not to scale yet but it’s not that far in the future.”