Ensuring Quality and Reliability in Automotive Software Development: An Overview of ASPICE 4.0

ASPICE (Automotive SPICE) 4.0 is a process assessment model tailored specifically for the automotive industry to ensure the quality and reliability of software and system development processes. It is part of the larger ISO/IEC 330xx family of standards and is derived from the general SPICE (Software Process Improvement and Capability determination) framework.

Key Features of ASPICE 4.0

- Process Reference Model (PRM): ASPICE 4.0 defines a set of processes relevant to automotive software and system development. These processes cover the entire lifecycle from requirements elicitation to maintenance. The PRM provides a comprehensive overview of essential activities and outcomes expected in each process.

- Process Assessment Model (PAM): The PAM provides detailed guidance on assessing the maturity of these processes. It includes indicators for evaluating the performance and capability of each process, helping organizations identify strengths and areas for improvement.

- Capability Levels: ASPICE 4.0 defines a six-level capability model, ranging from Level 0 (Incomplete) to Level 5 (Optimizing). Each level builds on the previous one, with Level 1 focusing on basic performance, and higher levels emphasizing increasingly sophisticated process management and continuous improvement.

- Automotive-specific Focus: Unlike general SPICE models, ASPICE 4.0 addresses the unique requirements of automotive systems, including compliance with safety standards such as ISO 26262. It emphasizes processes that are critical for developing safe, reliable, and high-quality automotive software and systems.

- Traceability and Compliance: ASPICE 4.0 ensures that all processes are well-documented and traceable, facilitating compliance with regulatory and industry standards. This traceability is crucial for audits and assessments, providing a clear linkage between requirements, design, implementation, and verification.

- Scalability and Flexibility: The model is designed to be scalable, allowing organizations of different sizes and complexities to adopt and implement its processes. It provides flexibility to tailor the processes based on specific project needs while maintaining the core principles of quality and reliability.

Benefits of ASPICE 4.0

- Improved Quality: By following structured and well-defined processes, organizations can enhance the quality of their software and systems, reducing defects and failures.

- Risk Management: ASPICE 4.0 helps in identifying and mitigating risks early in the development process, particularly those related to safety and compliance.

- Customer Confidence: Adherence to ASPICE 4.0 standards demonstrates a commitment to quality and reliability, fostering trust and confidence among customers and stakeholders.

- Competitive Advantage: Organizations that achieve higher capability levels can differentiate themselves in the market, showcasing their proficiency in delivering high-quality automotive solutions.

RELATED: Best Practices to Accelerate Your Automotive Spice (ASPICE) Capabilities

With ASPICE 4.0, there are several changes to the previous version, including:

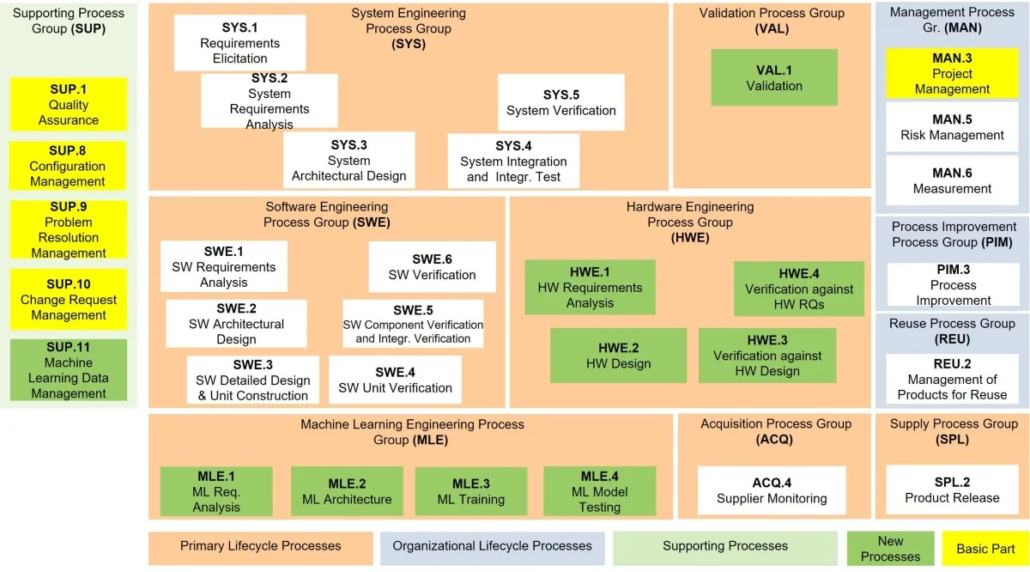

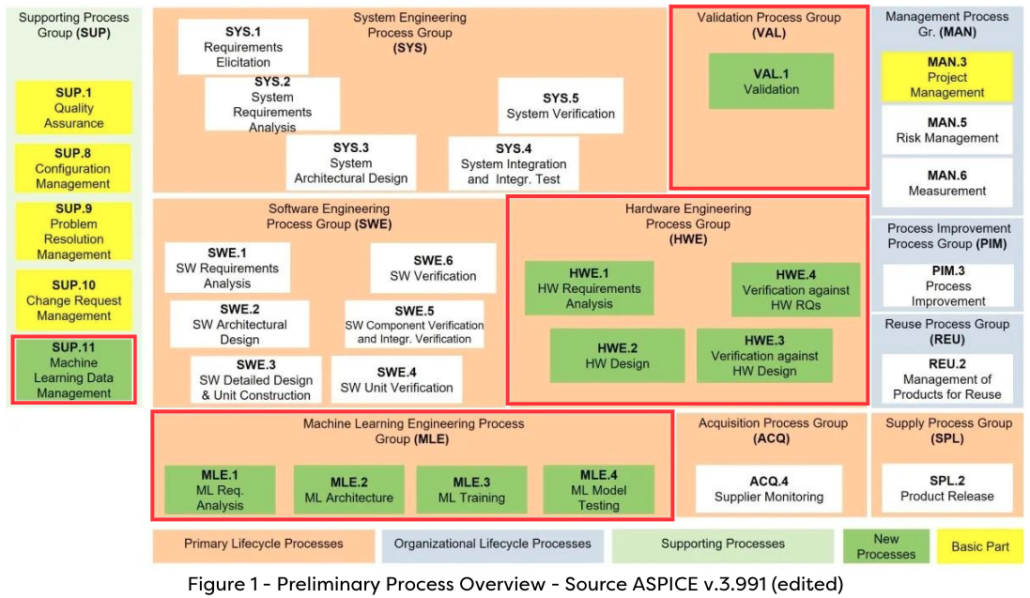

A revised process landscape to better cover essential development activities of modern mechatronic systems and to reflect modern collaboration models more accurately, addressing increasing complexity due to digitization, automation, and artificial intelligence (AI).

Figure 2 – Automotive SPICE process reference model – Overview

image source: Invensity

Inclusion of processes to address Machine Learning (MLE.1 – MLE.4) and hardware development (HWE.1 – HWE.4), as well as adding a validation process for the overall system (VAL.1) and a support process for data management in machine learning (SUP.11).

Strategy documents are now required from Capability Level 2 instead of Level 1, changing their role and the approach to managing versus executing processes.

image source: Invensity

A shift from focusing on “Work Products” to “Information Items”, which emphasizes the main results of processes as indicators rather than specific documents, and combining base practices that consider traceability and consistency into a common base practice.

A push towards maximum repeatability and reproducibility of assessment results to reduce subjectivity and eliminate redundancies, leading to more efficient assessments and avoiding misinterpretations. Additional terminology to keep aligned with other standards.

A new Training model focusing on varying degrees of knowledge necessary and specialties:

image source: Invensity

RELATED: Jama Connect® for Automotive

Jama Connect for Automotive is designed to help you get ramped up quickly with a single platform, training, and documentation aligned to industry standards and regulations including ISO21434:2021, ISO 26262:2018, and ASPICE, while applying a proven systems engineering approach to product development.

Download this solution overview to find out what’s included in Jama Connect for automotive, including:

- Frameworks aligned to key industry regulations

- Procedure and configuration guides specific to automotive manufacturing activities

- Consulting and training customized to your teams’ automotive product development processes

Note: This article was drafted with the aid of AI with additional content, edits for accuracy, and industry expertise by Matt Mickle and McKenzie Jonsson.

- 9 Strategies To Overcome Challenges In The EU Medical Device Market In 2025 And Beyond - February 6, 2025

- Leveraging Jama Connect® and Jira for Enhanced Requirements - January 30, 2025

- With Hacks on the Rise, Manufacturers Hone Their Cybersecurity Smarts - January 23, 2025