In Part II of our six-part automotive series, our experts discuss how to ensure functional safety compliance using Jama Connect for Automotive. If you’re new to our Automotive Development blog series, you may want to go back and read Part I and the Series Intro.

While safety has long been an important aspect of developing automotive systems, traditional safety considerations have largely involved mechanical systems. The modern automobiles, however, are increasingly relying on electronic systems and significant amounts of software. This increase in electronics in vehicles brings in new considerations when it comes to functional safety compliance.

Note: Now that our automotive development blog series has concluded, you can go back and read series intro and Part I.

Functional Safety Compliance: ISO 26262

The standard that is concerned with the functional safety of electronic systems is ISO 26262. ISO 26262 is actually a series of standards that provides a framework for developing both electronic hardware and software systems where functional safety must be achieved. The standard describes a process for identifying risks in a system and provides guidance for mitigating those risk. The guidance is provided in the form of requirements and processes that are understood by the industry as the current state of the art for achieving functional safety.

RELATED: Watch a demonstration of the Jama Connect for Automotive Solution

A major component of ISO 26262 is a robust series of processes for requirements management and traceability. The processes require that organizations develop safety goals, translate those into functional requirements, technical requirements, and eventually both hardware and software requirements as appropriate for the system. The system must then be fully verified against all requirements and specifications. Critically, the processes require that traceability between the requirements, specifications, and verification activities be maintained and all documentation carefully reviewed.

Jama Connect for Automotive

A requirements management tool like Jama Connect for Automotive reduces the manual effort required in adhering to ISO 26262. Jama Connect for Automotive’s traceability features are ideally suited to maintaining and analyzing the required traceability. The review features are the ideal way to ensure documentation is fully reviewed and approved by a cross-functional team. The export features generate well-formatted documents for many of the work products required by ISO 26262.

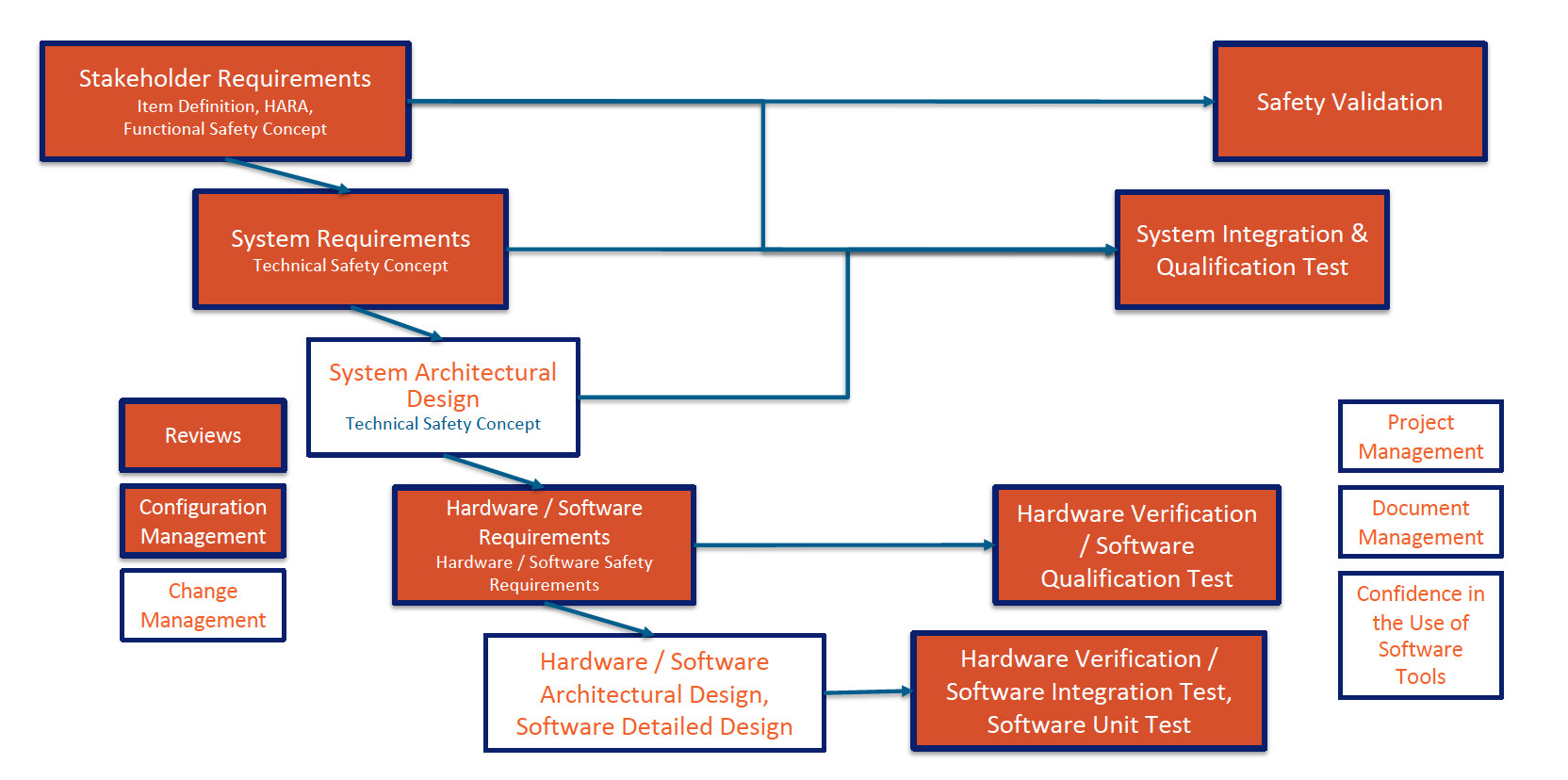

The flow diagram below summarizes the ISO 26262 processes that can be managed in Jama Connect for Automotive. The boxes with an orange border represent the recommended work products to be captured in Jama Connect for Automotive. The boxes with a gray border represent the work products that benefit from being captured in Jama Connect for Automotive, but some organizations might choose to capture elsewhere.

RELATED: Learn more about the Jama Connect Functional Safety Kit for Automotive Teams

High-Level ISO 26262 Process in Jama Connect for Automotive

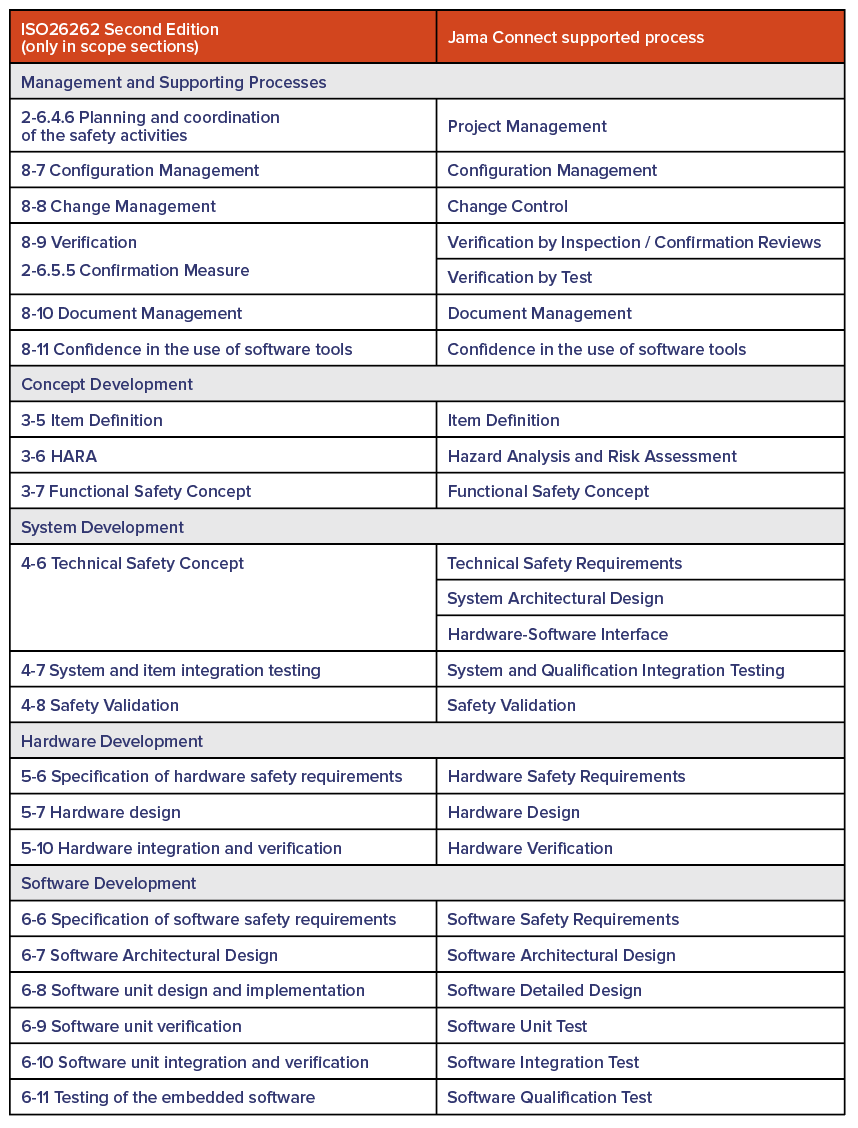

Jama Connect for Automotive includes a fully functional framework that software teams can use to start getting value immediately. This includes complete documentation for how to complete each process most efficiently in Jama Connect for Automotive. Industry-specific Professional Services are also included to guide customers through the inevitable customizations needed by each organization. A complete list of the processes for working in Jama Connect for Automotive that align with ISO 26262 are listed in the table below.

ISO 26262 Alignment to Jama Connect Processes

To learn more about how Jama Connect for Automotive can help your team simplify compliance, streamline development, and speed time to market, download our solution overview.

Learn more about the Jama Connect Functional Safety Kit for Automotive Teams

- Safety as a Competitive Advantage - October 6, 2021

- Part II: How to Ensure Functional Safety Compliance with Jama Connect for Automotive - September 17, 2020

- Part I: [Answered] How to Accelerate Your Automotive SPICE (ASPICE) Capability - September 10, 2020