In this blog, we preview a section from the new eBook, “CIMdata: Digital Thread in Aerospace and Defense”

Click HERE to download it.

Recent CIMdata research on behalf of the Aerospace and Defense PLM Action Group member companies in collaboration with PTC clearly indicates that digital thread investment within the ecosystem of industrial users, their customers, suppliers, and solution providers is poised for rapid growth. Initial implementations of targeted digital thread solutions have provided proof points of value and essential learnings. Now, rounds of investment are ramping up, guided by these early achievements and with expectations driven by the value potential revealed.

The concept of a digital thread providing automated linkage of multiple representations of a product, each tuned to the needs of various creators and consumers along the lifecycle, is very powerful. Until recently, tracing these linkages has been primarily a manual process, extracting product information from myriad heterogeneous systems and relating them in ad hoc reports. But now, with recent advances in commercial PLM solutions, the digital thread, with automated linkages and traceability, has become a practical possibility, even for industries with complex products, such as aerospace & defense.

In response, industry leaders have implemented targeted digital thread solutions and envision expanding these solutions throughout the product lifecycle. With the newness of this approach there is not much available in the way of lessons learned or value achieved. This lack of real data is a barrier to broader investment within industry. On the solution side, providers are constantly seeking additional insight into investment drivers within industry.

Future Digital Thread Investment Priorities

Looking to the future, industry leaders are taking a broader view of the digital thread’s value potential, with more investment in production and service use cases. They view the next stage as more complex and transformative to their companies. Fortunately, several have been successful in establishing programs that enjoy strong support from a well-informed and motivated senior management. However, many others have not.

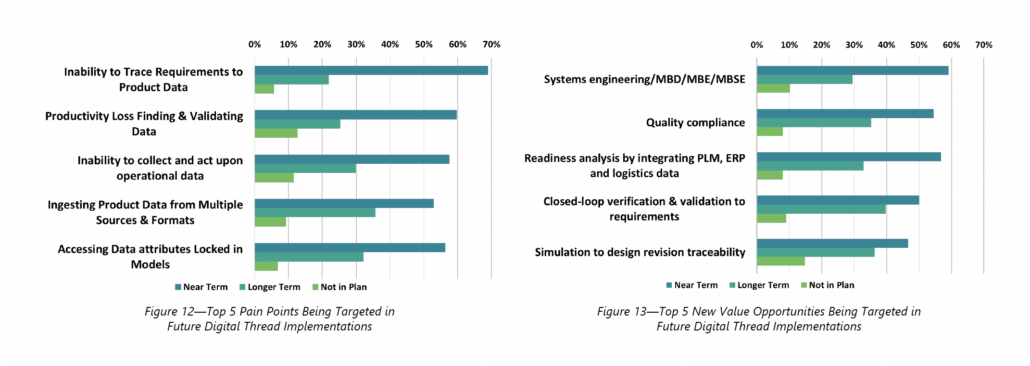

All Top 5 pain points being targeted in future implementations relate to accessibility and traceability across data elements, especially traceability of requirements throughout the product lifecycle. Systems engineering is featured prominently in many responses, including ranking as the top new value opportunity being targeted in future digital thread implementations, which aligns with CIMdata’s view that systems engineering is a principal driver of the digital thread.

RELATED: Requirements Traceability Diagnostic

Strategies for Success

An area of divergence between industry leaders is in the focus of their implementations. For some, the focus is providing interfaces to source applications to extract and associate product data artifacts and attributes. For others, the key is the association and traceability of dependencies between artifacts in support of a use case. And for a few, the focus is on data governance, which they believe is foundational for enabling a richer and more extensive set of product lifecycle use cases.

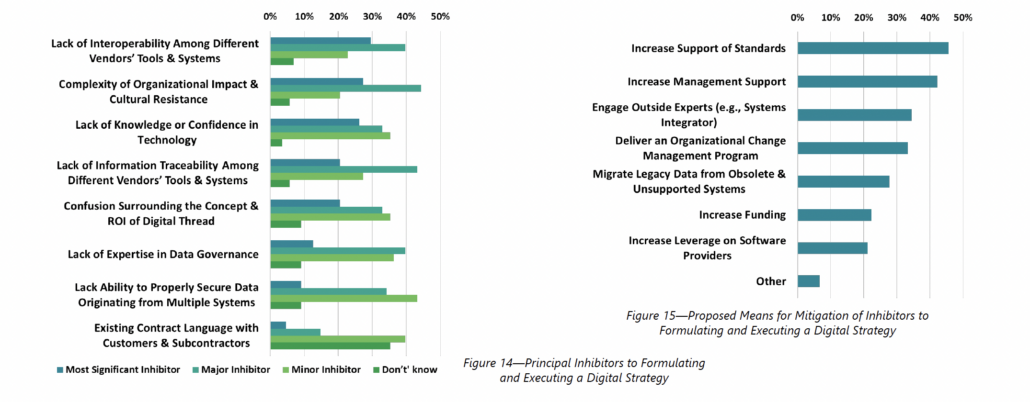

The number one inhibitor to formulating and executing a digital thread strategy is “lack of interoperability between different vendors’ tools and systems.” The number one proposed means for mitigation is to “increase support of standards.”

Solution Technologies

Key Technical Considerations

Core to the value of digital thread is traceability across multidiscipline sources and derivative product-related artifacts along the product lifecycle and throughout the extended enterprise.

The digital thread value landscape is distributed across a heterogeneous value chain from customer to OEM to partners and multiple tiers of suppliers. This reality drives the need for data interoperability and elevates the importance of standards and openness of enabling solution architectures.

Proven technical solutions exist for enabling the digital thread, and leading solution providers are investing heavily in research guided strategies and roadmaps to further strengthen their offerings.

Data is the foundation of the digital thread. This reality elevates the importance of sound data governance and a cleansed repository, especially as use case implementations proliferate and must be interlinked into an extended thread.

Technologies in Use Today

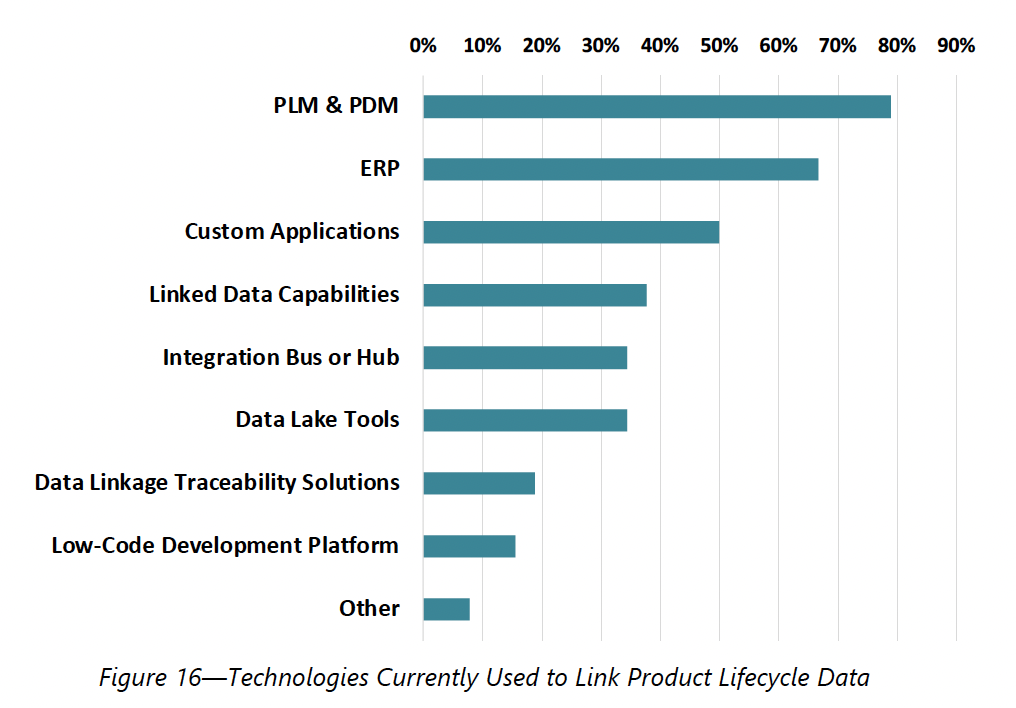

The technologies used to link product lifecycle data segregate into three tiers as shown in Figure 16. The top tier, which has the longest history, includes PLM and PDM, followed by ERP, and custom applications. The middle tier consists of application and data integration tools. These are followed by the third tier of newer specialty technologies for combining data from multiple sources and establishing linkages and traceability. We can expect the ranking of these specialty technologies to rise significantly over the next few years.

Solution Capability and Provider Alignment

Attitudes on the topic of solution capability and provider alignment are mixed. Some industry leaders are quite critical, especially regarding data model accessibility and flexibility to comply with a corporate data governance strategy. Other interviewees are somewhat neutral or slightly positive. They feel that some providers are moving in the right direction; some are not. Several feel that solution capabilities have improved significantly overall in the last 5-10 years and that, despite some remaining gaps, are now fully capable. Some express satisfaction that “good partnering” is happening.

RELATED: Reduce Project Risk in the Product Development Process

Jama Software® Solutions

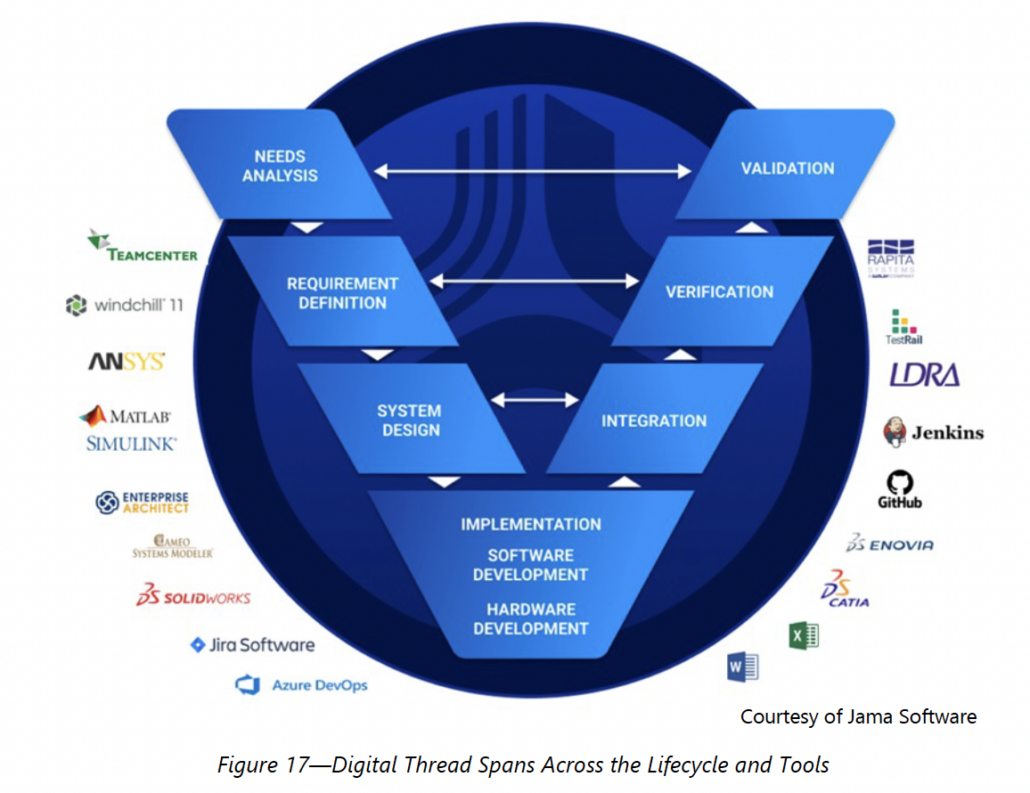

Jama Software®’s industry-leading platform, Jama Connect®, helps teams manage requirements with Live Traceability™ through the systems development process for proven cycle time reduction and quality improvement. The number-one problem product engineering organizations face is managing requirements traceability spanning siloed teams and tools (e.g., design, hardware, software, test, risk, quality) which creates an increased risk of negative outcomes such as extensive rework, delays, and cost overruns.

Jama Connect enables digital engineering for innovative organizations in aerospace, automotive, medical, and industrial verticals. The future of product development relies on agile and transformative digital engineering techniques. Jama Connect helps customers solve their toughest challenges and simplify complex mission-critical system development across complex partner and supplier ecosystems.

Jama Connect seamlessly integrates with the product development technology stack. Organizations can take advantage of Jama Connect’s integration solutions with market-leading tools for design and simulation, task management, lifecycle management, quality assurance, and testing. Teams can work in their preferred tools while ensuring all requirements are verified and validated to achieve complete traceability.

Live Traceability with Jama Connect Delivers:

- 1.8X faster time to defect detection

- 2.1X faster time to execute test cases

- 2.4X lower test case failure rates

- 3.6X higher verification coverage

Jama Software’s benchmark study for monitoring and measuring traceability through its Traceability Score™ has shown that companies that have a higher traceability score in the digital thread have faster cycle times and defect detections. This allows companies to be nimble and be twice as fast in releasing products vs. companies that do not monitor and measure traceability in their product lifecycle. Requirements Traceability Benchmark

This has been an excerpt from the eBook, “CIMdata: Digital Thread in Aerospace and Defense”

Click HERE to download the full version.

- 9 Strategies To Overcome Challenges In The EU Medical Device Market In 2025 And Beyond - February 6, 2025

- Leveraging Jama Connect® and Jira for Enhanced Requirements - January 30, 2025

- With Hacks on the Rise, Manufacturers Hone Their Cybersecurity Smarts - January 23, 2025