Ensuring Aerospace Compliance to Regulatory Requirements

Ensuring Aerospace Compliance to Regulatory Requirements

We are in a time of unyielding technological development. It is not unlike the “giant leaps” made by the US Space program in the 1960s. The technology available to us in our everyday lives and certainly in the Aerospace and Defense industry is staggering.

Think about when you got your first cell phone. Remember those famous Motorola flip phones?

That was only 20 years ago. As I write this, I’m listening to digital music on my Galaxy Note through Bluetooth headphones typing on a touchscreen laptop that weighs like two lbs. Conversely, the Apollo program had less computing power than my 1993 vintage engineering calculator and the space shuttle had 1MB RAM while my Galaxy Note has 128GB plus the SD card. And this is close to obsolete, at all of two years old. We take things for granted: Alexa, smart cars, 4G data. But the technological development behind them is non-stop.

I should introduce myself. My name is David Ewing. I recently joined Jama Software as Principal Solution Architect for A&D. My background is in Enterprise PLM (Product Lifecycle Management) both on the industry and the software supplier side. Most recently at Aras I spent time as a Product Manager, Product Marketing Manager, and Technical Account Manager for A&D.

Aerospace Compliance Can Require a Significant Effort

Developing new technology and innovative products in a heavily regulated industry like aerospace entails a significant amount of effort spent ensuring that requirements are understood and verified. Requirements from the customer typically relate to features, performance, cost, etc. As an example, let’s use airline seats – because we can all relate to them. When an airline orders seats for their shiny new fleet of aircraft they are specifying things like weight, in–flight entertainment, cushions & covers, and recline geometry. They are interested in the environment for the passenger, the cost per mile, etc. They are absolutely concerned about safety. However, the base safety requirements come from the regulatory body – FAA or EASA (European Union Safety Agency).

A crash test dummy before its accelerated down the track. Photo by Christine Negroni

Conversely, the FAA is concerned with airworthiness and compliance to a boatload of regulatory requirements. Things like the spacing from the cabin walls is specified as is the aisle width to support egress and passage of the elbow biting beverage cart (that’s why your seats are narrow!). The FAA does not care about the fancy TV monitor, they care what happens when your head hits it during a tarmac accident. They don’t care about the luxurious leather and fabric designs; they care about the flame spread and amount of toxic smoke that they release should something bad happen. Every piece of nonmetallic material in an aircraft seat is tested for flammability and toxicity. Most importantly, the FAA cares about crash worthiness should something unexpected happen. All aircraft seats are put through a number of simulated crash tests to make sure those seats stay attached to the airframe, the food trays stay stowed, and you can get to the floatation devices. This is also the fun part – Engineers love to break things!

Keeping track of all this information is no small task. The number of Code of Federal Regulations (CFR), Advisory Circulars (AC), Technical Standard Orders (TSO) is a mountain of information in its own right. And we are not even talking about a flight critical system like the avionics. Furthermore, we haven’t even added the customer requirements yet.

Managing Requirements for Certification

Existing aerospace firms have entire certification departments to support the regulatory requirements and program managers to handle the customer side of things. The amount of Non-Value Added (NVA) work that is applied to managing requirements and certification is staggering. Engineers that are hired to help to perform the actual certification testing spend a significant amount of their time acting as a librarian.

If managing requirements and validation is so hard, how is a new startup supposed to deliver innovative new products? Or how can the existing aerospace firm reduce NVA work to speed time to market and reduce costs? With a solution created for the airborne systems developer, that’s how! Enter Jama Connect for Airborne Systems.

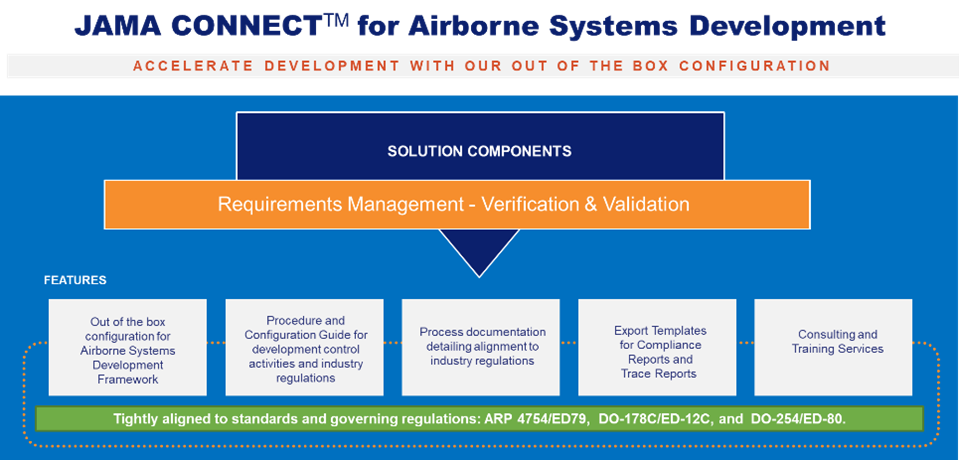

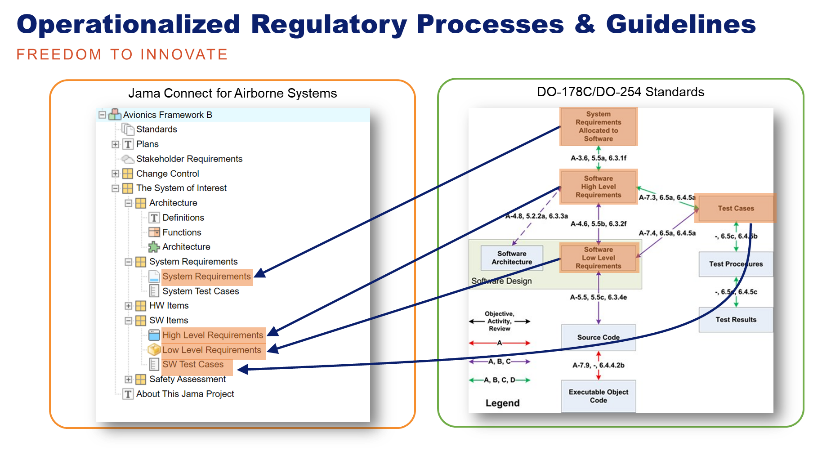

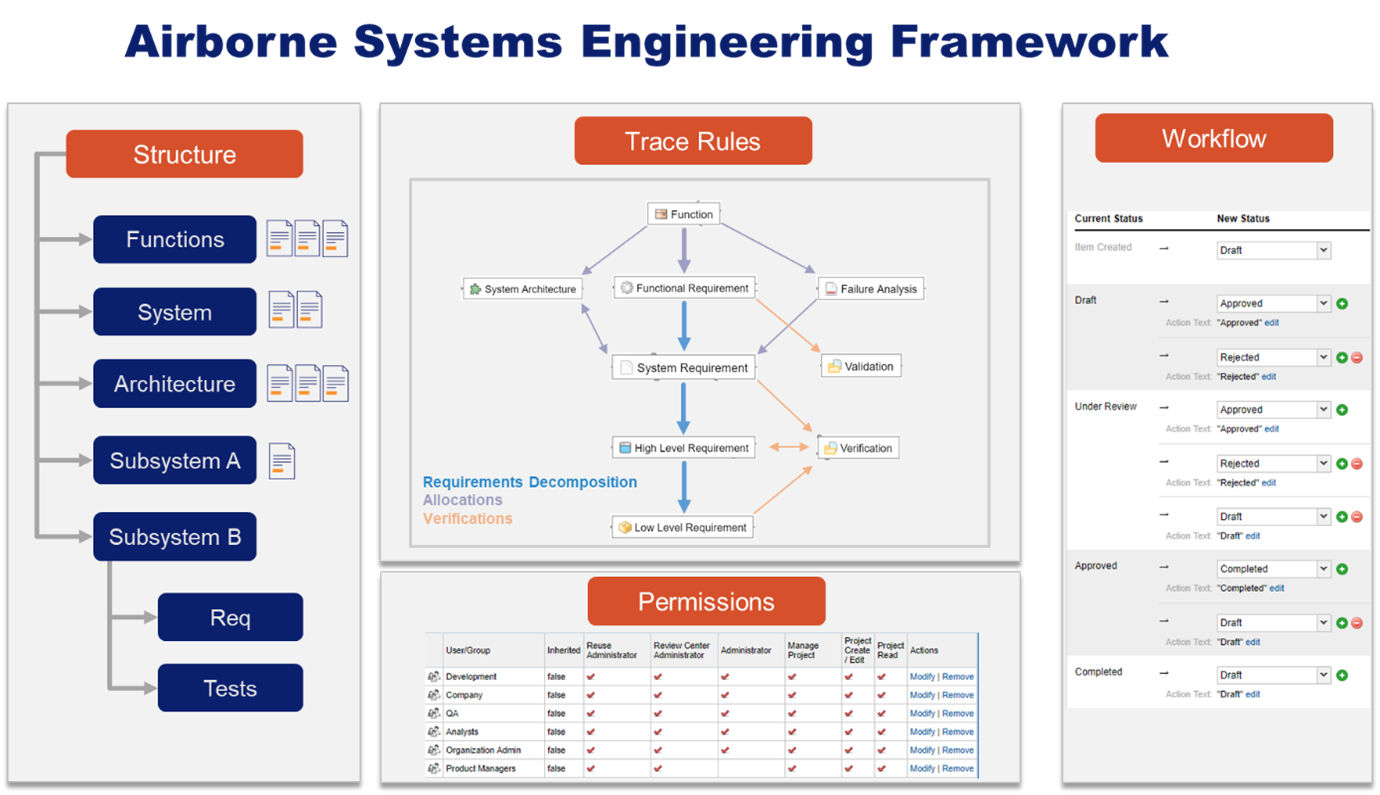

We have created an industry focused solution for airborne system developer. It is the hot fudge sundae with sprinkles and cherry on top to legacy tools vanilla requirements management. Jama Connect for Airborne Solution is pre-configured with item types, pick lists, relationships, project & import/export templates. All these features are directly aligned with regulatory guidelines like ARP4754 and DO178.

Developing Hardware and Software in Sync

We know airborne systems require extremely rigorous integrated development assurance processes. System architecture, hardware, and software must be developed together, in concert, and then validated against the certification requirements. To demonstrate compliance with airworthiness requirements, certification agencies accept the use of the noted industry guidelines. By embedding them into the Jama Connect for Airborne Systems solution we operationalize the processes and free you from the overhead of creating and managing the digital infrastructure – so you can focus on innovation.

Your hire talented engineers to develop innovative new products – not be a librarian for documents and standards. With Jama Connect for Airborne systems we free your team to innovate – we will take care of the record keeping!

If you are interested to learn more about the Jama Connect for Airborne Systems Solution, I’ll be hosting a webinar tomorrow, April 14. We will give an overview of the solution and a demonstration. Additionally, we have information you can read at your leisure on our website. Or if you want to chat, reach out to me directly – dewing@jamasoftware.com. I am always happy to talk shop!

To learn more about how Jama Connect for Airborne Systems helps teams to improve their ability to communicate, track, and test requirements for teams in the aerospace industry, download our solution overview.

- Yes, Jama Connect Works with Your PLM – And Here’s How - May 31, 2021

- Aerospace Compliance: When Failure Is Not an Option - April 13, 2021