Jama Software is always on the lookout for news and content to benefit and inform our industry partners. As such, we’ve curated a series of articles that we found insightful. In this blog post, we share content sourced from AI Multiple – 15 Digital Twin Applications/ Use Cases by Industry in 2022 – which was originally published on April 25, 2022, by Cem Dilmegani.

15 Digital Twin Applications and Use Cases by Industry in 2022

Digital twin technology is becoming more widespread. According to Deloitte study, the global market for digital twins is expected to grow with 38% CAGR to reach $16 billion by 2023, and the proliferation of IoT technology accelerating this growth.

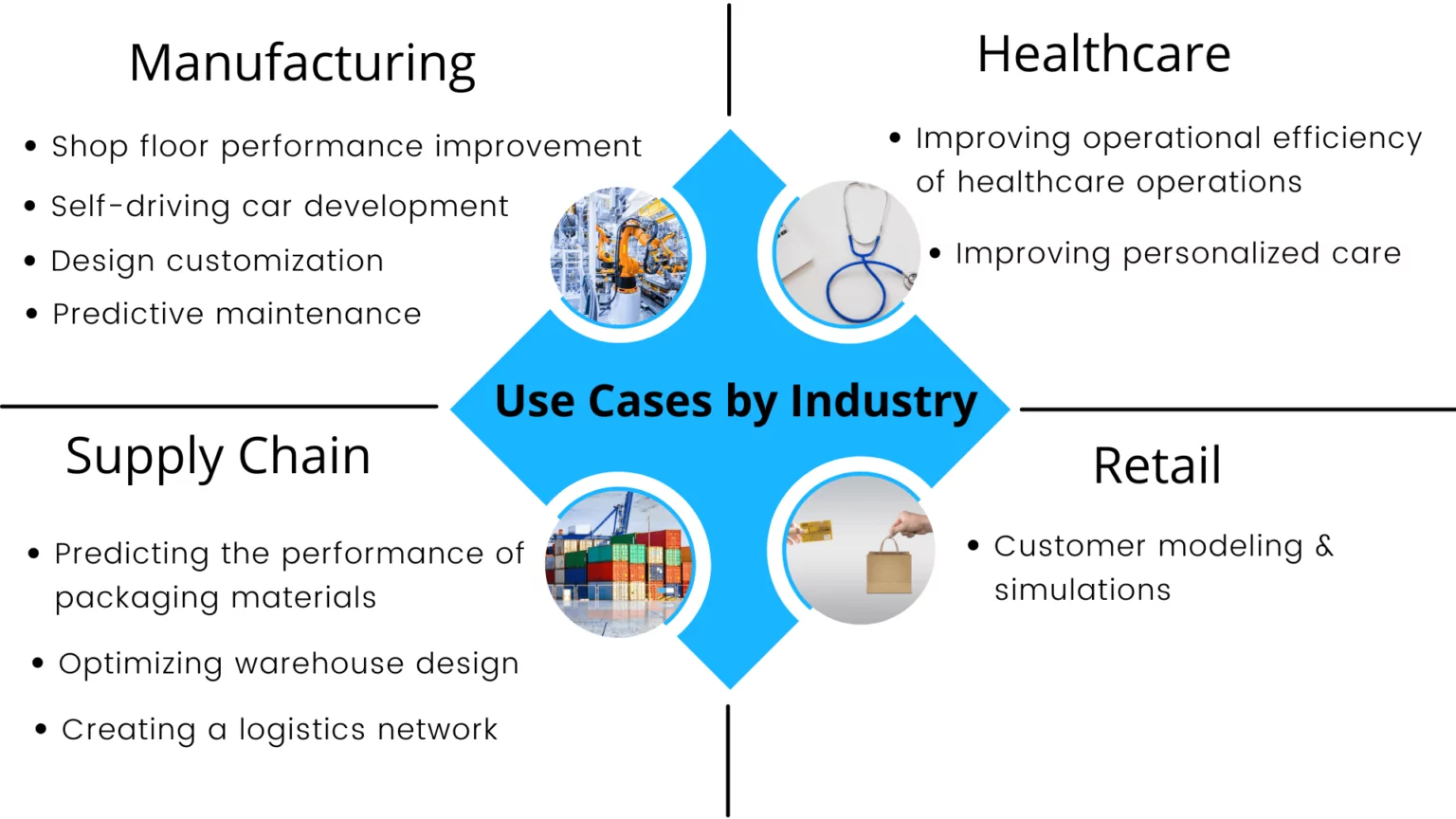

A digital twin is a virtual/ digital replica of physical entities such as devices, people, processes, or systems that help businesses make model-driven decisions. Digital twins are changing the way work is done in different industries with varying business applications. Knowing those applications can help businesses implement digital twins into their processes. Therefore we examined digital twin applications in manufacturing, healthcare, supply chain and retail. And we created the list of digital twin use cases, applications and examples.

Supply Chain

Digital twins are also widely used in the supply chain/logistics industry. Some applications are:

Predicting the performance of packaging materials

Product packaging can be virtualized and then tested for errors before being packaged. Digital twins help logistics companies determine material feasibility.

Enhancing shipment protection

Logistics companies can analyze how different packaging conditions can affect product delivery with the help of digital twins.

Optimizing warehouse design and operational performance

Digital twins enable logistics companies to test warehouse layouts so companies can choose the most efficient warehouse design to maximize operational performance.

Creating a logistics network

A digital twin of a road network carries information about the traffic situation, road layout, and construction. With that knowledge, logistics companies can design the distribution routes and inventory storage locations.

Construction

A digital twin can help construction firms understand how a building is performing in real-time, which allows them to tweak performance to optimize efficiency. Data collected from digital twin can be used for planning and designing future buildings.

Healthcare

Digital twins can help healthcare providers virtualize healthcare experience to optimize patient care, cost, and performance. For healthcare, use cases can be categorized into two groups:

Improving operational efficiency of healthcare operations

Creating a digital twin of a hospital, operational strategies, capacities, staffing, and care models helps healthcare providers examine the operational performance of the organization.

Improving personalized care

Healthcare providers and pharma companies can also use digital twins to model the genome code, physiological characteristics, and lifestyle of patients so that healthcare companies can provide personalized care such as unique drugs for each patient.

Related: 2022 Predictions for Medical Device Development: Increased Focus On Cybersecurity, Clarity On Standard Compliance, and the Challenge of Human Variability

Manufacturing

Applications of digital twins are most widely used in the manufacturing industry. Manufacturing relies on high-cost equipment that generates a high volume of data which facilitates creating digital twins. Digital twin applications in manufacturing are as follows:

Product development

Digital twins can help engineers test the feasibility of upcoming products before launching. According to the test results, engineers start producing or shift their focus to creating a feasible product.

Design customization

With digital twins, businesses can design various permutations of the product so that they can offer personalized products and services to their customers.

Shop floor performance improvement

A digital twin can be used to monitor and analyze end-products and help engineers see which products are defected or has lower performance than intended.

Predictive maintenance

Manufacturers leverage digital twins to predict potential downtimes of machines so that businesses minimize non-value adding maintenance activities and improve the overall efficiency of machines since technicians take action before a failure happens.

However, using digital twins for predictive maintenance tasks is not scalable as it is a machine-specific virtual replica and requires expensive data science talent to build and maintain twins.

For more info on digital twin applications in manufacturing, feel free to check our article about AI applications in manufacturing where we explain each application.

In aerospace and automotive manufacturing, there are further applications of digital twins:

Aerospace

Before digital twins, physical twins were used in aerospace engineering. An example is Apollo 13 program in the 1970s where NASA scientists on earth were able to simulate the condition of the ship and find answers when critical issues arose. Later in 2002, the digital twin concept is introduced by John Vickers from NASA.

Today the importance of digital twins in the aerospace industry is acknowledged by experts that 75% of air force executives have cast the vote of confidence in favor of the digital twin, according to Business Wire’s survey report.

With digital twins, engineers can use predictive analytics to foresee any future problem involving the airframes, engine, or other components to ensure the safety of the people onboard.

Related: Jama Connect® for Aerospace and Defense

Automotive

Developing new cars mostly takes place in a virtual setting. Digital Twins are used in the automobile industry to create the virtual model of a connected vehicle. Automotive companies use the technology to design the ideal automotive product even before production starts. They simulate and analyze the production phase and the problems that might occur once the vehicle hits the roads.

Self-driving car development

Though digital twin practices can be used in the traditional automotive manufacturing industry, digital twins are handy for autonomous vehicle companies. Self-driving cars contain numerous sensors that collect data regarding the vehicle itself and the environment of the car. Due to the liability questions that surround autonomous vehicles, creating a digital twin of a car and testing every aspect of the vehicles is helping companies ensure unexpected damage and injuries will be minimized. Some applications of digital twins in the automotive industry are road testing and vehicle maintenance.

For more on digital twin applications in manufacturing, feel free to watch the video of Dr. Norbert Gaus who is head of R&D in Automation and Digitalization at Siemens. He is explaining how digital twins help streamline the production process in the real world and providing examples:

Retail

Customer modeling & simulations

Retailers can create digital twins of customer personas to improve the customer experience they deliver. For example, retailers can provide ideal fashion clothing products to customers based on their digital twin models.

Finally, you can view our data-driven list of digital twin software to find the best solution that suits your business needs. If you still have questions about digital twin applications, we would like to help:

RELATED

- 9 Strategies To Overcome Challenges In The EU Medical Device Market In 2025 And Beyond - February 6, 2025

- Leveraging Jama Connect® and Jira for Enhanced Requirements - January 30, 2025

- With Hacks on the Rise, Manufacturers Hone Their Cybersecurity Smarts - January 23, 2025